Haihao Group’s Engineers make WPS for welding of pipe spools

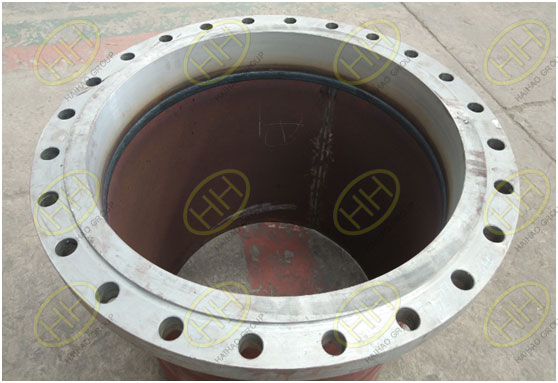

Pipe spools are fabricated from components, these components may be steel pipe, flanges and pipe fittings. They could be connected together by welding or thread. WPS are necessary for welding of pipe spool. What is WPS? Why our engineers must make WPS?

Welding Procedure Specification (WPS) is a formal document which describes welding procedures. WPS could provide direction to our welders to make reliable and high-quality production welds according to the requirements of customers. The aim of this document is to guide our welders to the acceptable procedures so that repeatable and trusted welding techniques are used for the pipe spools.

The material of pipe spools are ASTM A516 Gr.60, welding type is manual. The WPS is supported by a Procedure Qualification Record (PQR or WPQR). A PQR is a record of a test weld performed and tested (more rigorously) to ensure that the procedure will produce a good weld. Our engineers had made PQR in advance. In addition, our welders are also certified with a qualification test documented in the Welder Qualification Test Record (WQTR) that shows they have the understanding and demonstrated ability to work within the specified WPS.